Research & Development

Global Leading Company

Home > Research & Development > Secondary battery cathode material

Secondary battery cathode material

Secondary battery cathode material

Lithium Secondary Battery Cathode Materials

Currently, Li-ion batteries, the most widely used commercially, are witnessing an explosive demand, with an annual growth rate of over 13%, largely driven by the surge in electric vehicle adoption. In particular, demand for anode materials is projected to grow by over 30% annually. However, Li-ion batteries face significant technological challenges in enhancing energy density, which determines battery runtime. To overcome this, domestic electrode material manufacturers are focusing on developing new high-capacity anode materials. Additionally, silicon is gaining attention as a next-generation anode material that can significantly increase energy density per weight and volume compared to conventional graphite anodes.

01 Silicon, Carbon, Graphite Composite Anode Material

- Currently, anode materials are primarily composed of graphite arranged in a regular layered structure, divided into natural and artificial graphite. Natural graphite, once the most stable and cost-effective material for storing lithium ions, has seen a decline in structural stability due to expansion issues during use, leading to a gradual increase in the usage of artificial graphite. Artificial graphite, created through high-temperature processing of over 3000°C, exhibits higher crystallinity and uniform structure compared to natural graphite, resulting in increased stability.

- Silicon anode materials offer approximately ten times higher energy density compared to conventional graphite-based anodes, allowing for increased driving range in electric vehicles and easier design for rapid charging. Moreover, silicon is environmentally friendly and abundant on Earth, making it an economically viable material. However, silicon anodes suffer from approximately fourfold expansion during battery charging, posing a challenge. Research and development efforts are focused on stabilizing the silicon structure, as overcoming this volume expansion issue is crucial for securing market leadership.

- One proposed solution to address these challenges is the manufacturing technology for silicon-carbon-graphite composite anode materials. This technology aims to maximize the advantages of silicon anodes while suppressing the drawbacks such as volume expansion, thereby meeting the demands of battery market.

- By controlling the size of silicon particles, it becomes possible to manufacture a wide range of composite electrode materials. Moreover, it's feasible to control the size of composite materials, consisting of silicon particles and surface performance enhancers, at the micron level.

- With 5% compositeization it exhibited 100% efficiency up to 300 cycles with an initial capacity of 500mAh/g.

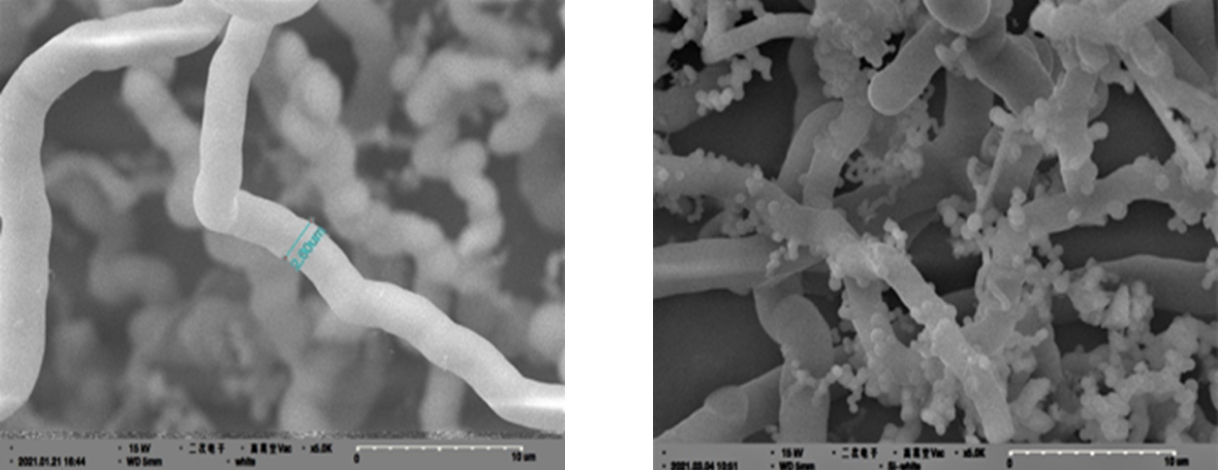

02 Fibrous Silicon Anode Material

- The silicon anode materials currently being developed are in the form of particulate powder, necessitating complex processes for electrode application and essential control of particle distribution. However, fibrous silicon anode materials, which are in a non-woven fabric form, offer significant advantages not only in the electrode manufacturing process but also in controlling electrode density and bonding with the copper collector.

- The silicon is in fibrous form, with some exhibiting characteristics of resin.

- Fibrous silicon can also be produced in nonwoven fabric form, thus offering potential applications as a completely new type of cathode material for lithium-ion batteries. Moreover, as the crystallization of fibers is achievable through high-temperature processing, it opens up possibilities for the development of various device materials.

03 Cathodic Surface Improvers

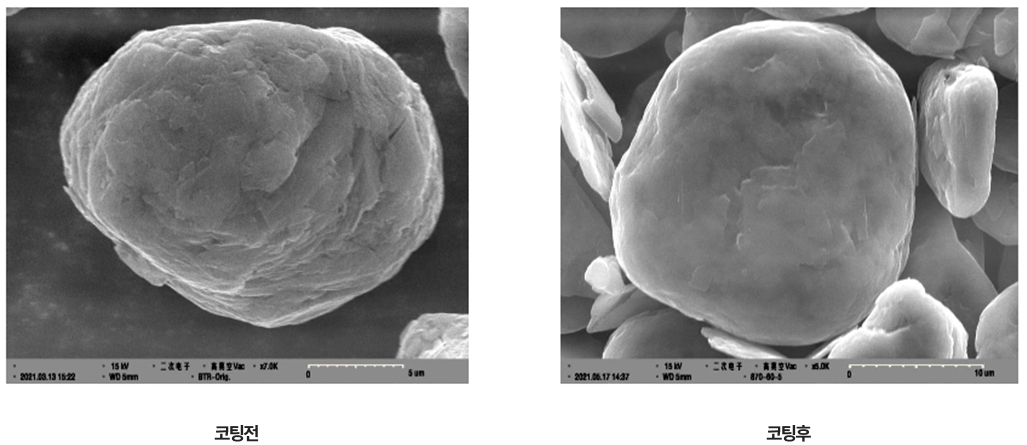

- Natural graphite-based cathode materials mainly use plate graphite as raw material, so a large amount of active sites and edges are exposed on the surface of the particles, and these plate particles not only have a high specific surface area, but also easily form dendrites by reaction with electrolyte, which causes performance degradation.

- The effect of spheroidization in improving electrochemical performance is to reduce the specific surface area of the particles and eliminate the exposed points at the edges, thereby improving the charge density and suppressing the formation of SEI layer.

- The specific capacity, primary charge/discharge efficiency and cycle characteristics of graphite cathodes can be significantly improved by spheroidisation, while the low specific surface area reduces the contact area with the electrolyte, thus inhibiting the formation of SEI layer, and the surface coating enables excellent performance improvement.

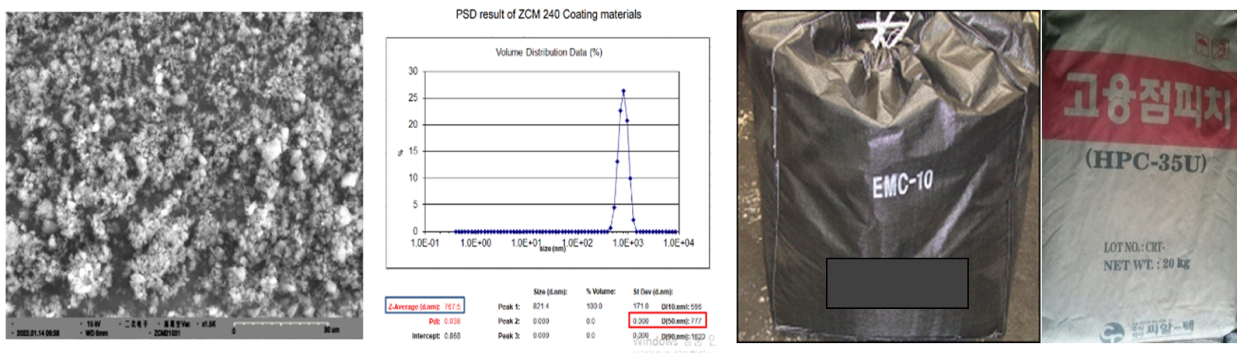

Dry Surface Performance Enhancer

- Our dry surface performance enhancer is an outstanding ultrafine powder with nano-sized particles, which, when coated on the surface of the cathode material, significantly enhances capacity and extends lifespan.

- We have been producing and selling this product to major corporations since 2010, and we possess all the engineering and technology required for production facility setup.

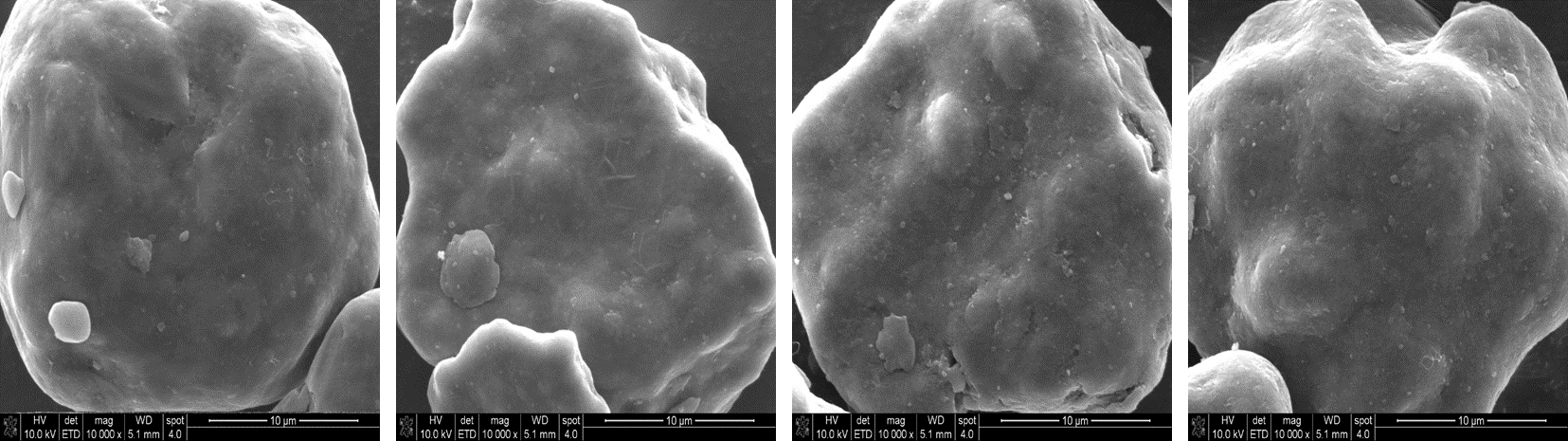

- The surface of the cathode material before the dry surface enhancer coating is bumpy, with many surface pores and cracks.

- However, after surface coating, the surface of the cathode material has become so smooth that no cracks or pores are visible.